Keeping food processing equipment in peak condition is essential for maintaining efficiency, ensuring product quality, and preventing costly downtime. REYCO Systems offers comprehensive repair services tailored to the unique demands of food processing facilities. With over 50 years of expertise in potato processing and frozen vegetables, our team delivers fast, reliable repairs that keep your operations running smoothly.

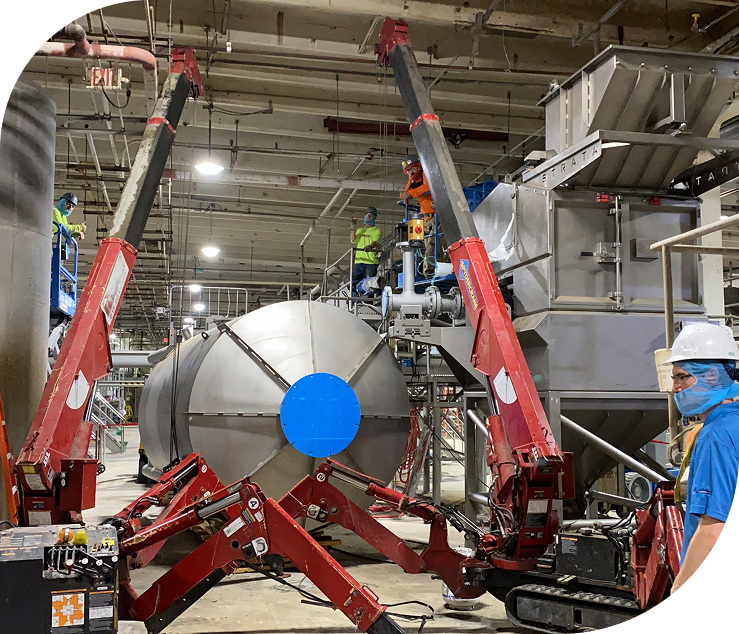

Food processing environments require durable, high-performing equipment, and when issues arise, quick and effective repairs are critical. Our repair services cover a wide range of needs, from mechanical support to custom welding and precision machining. Whether you need emergency fixes or preventative maintenance, our team is ready to respond with expert solutions.

With a focus on efficiency and reliability, our repair services help food processors reduce downtime, improve equipment longevity, and maintain compliance with industry regulations.

Unexpected equipment failures can disrupt production and lead to costly delays. Our break/fix services provide rapid response solutions to minimize disruptions and restore operations quickly. Whether it’s a malfunctioning conveyor system, damaged air makeup unit, or an issue with your fluid removal system, our team has the expertise to diagnose and resolve problems efficiently.

We understand that every minute of downtime affects productivity and profitability. That’s why we offer fast, on-site support to get your equipment back up and running as soon as possible.

Cornell Pumps are a vital component in many food processing facilities, providing the necessary power to move fluids efficiently. Instead of replacing a worn-out pump, a Cornell Pump rebuild can restore performance at a fraction of the cost. Our skilled technicians carefully disassemble, inspect, and rebuild pumps to extend their lifespan and improve efficiency.

Additionally, our spare parts services ensure quick access to high-quality replacement components. With over $2 million in OEM Cornell spare parts in stock, we provide fast identification and delivery to minimize downtime. As the largest Cornell representative in the Pacific Northwest, we offer laser pump alignment, in-house pump inspections, and expert assessments to optimize performance and prevent failures.

Food processing equipment operates under demanding conditions, making precision engineering a necessity. Our CNC machining services provide custom food-grade components designed to meet exact specifications, ensuring seamless integration with your existing systems.

Additionally, our custom welding services allow us to modify or repair equipment with precision. Whether fabricating replacement parts, reinforcing structural elements, or performing sanitary purge welding and combo welding, our expert welders ensure durability, compliance with food safety standards, and optimal equipment performance.

Preventative maintenance is one of the best ways to avoid costly breakdowns and extend the life of your equipment. Our tailored maintenance programs include routine inspections, system optimizations, and performance assessments to identify potential issues before they lead to failure.

By partnering with REYCO for preventative maintenance, food processing facilities can reduce repair costs, improve operational efficiency, and maximize equipment longevity.

“We Keep Your Equipment Running Smoothly, So You Can Focus on Your Business”

REYCO Systems is committed to delivering industry-leading repair solutions that enhance food processing efficiency and durability. Whether you need immediate repairs, component replacements, or long-term maintenance strategies, our team has the expertise to keep your equipment in peak condition.

Contact REYCO Systems today to learn more about our repair services and how we can support your food processing operations with fast, reliable solutions.

Partner with REYCO Systems, the industry leader in precision-engineered food processing solutions. Our cutting-edge technology enhances efficiency, reliability, and safety, helping food processors worldwide achieve peak performance. Contact us today to discuss how our innovative systems can elevate your operations.

Phone: (208) 795-5700

Fax: (208) 795-5749

Email: reycosales@reycosys.com

Address: 1704 Industrial Way Caldwell, ID 83605

© 2005 REYCO Systems, Inc. and/or its suppliers, 1704 Industrial Way, P.O. Box 460, Caldwell ID 83606-0460 U.S.A. All rights reserved. Any rights not expressly granted herein are reserved. WaterVac, EcoVac, EcoMiser, DynaMiser, VentPac, GasPac, and CoolPac are either registered trademarks or trademarks of REYCO Systems, Inc. in the United States and/or other countries. The names of actual companies and products mentioned herein may be trademarks of their respective owners. This Web site is intended for informational purposes only. REYCO Systems, Inc. makes no warranties, express or implied, as to the information in this Web site. Contact REYCO Systems, Inc. with questions or problems with this service.

© REYCO Systems 2025 | PO Terms and Conditions